Part 2 - Selecting a baseline spring specification for your car...

Part 1 - Tyres and Load Transfer

Springs are the first port of call when we look to improve the handling of our cars,

but what are we really trying to achieve by stiffening the suspension up? The biggest

benefits are reduced body roll and quicker response to steering inputs. They do have other

benefits in terms of aesthetics and geometry but they are not of concern for now.

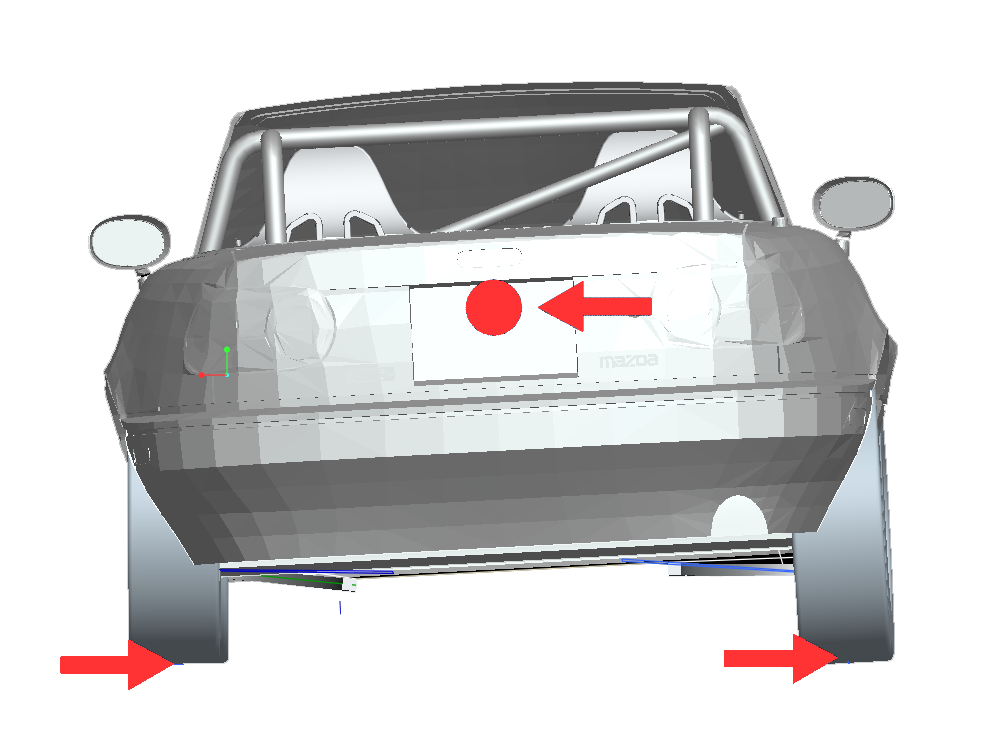

Body roll is a product of centrifugal (outwards) force acting upon the cars center

of gravity (CoG) with relation to the centripetal (inwards) force acting at the tyre

contact patches (See

Newton's 3rd Law). Because the CoG will always be above ground we create a torque

moment (the roll couple) between the CoG and the tyre contact patches (we’ll ignore

Roll Centre for now, I’ll cover that when I get round to geometry) that serves to

roll the sprung body mass outwards.

This roll is counteracted by a combination of

suspension geometry, springs and anti roll bars, which work alter the amount of

load the tyres see, remembering of course that the total load transfer remains the

same and thus is independent of roll.

Roll in itself is not bad, but the effects of it can be. The biggest downsides

of excessive roll are low transient stability and dynamic geometry change. The

former is something we are all familiar with in a softly sprung vehicle, fling

it through a series of corners in quick succession and it will flop from side

to side and generally feel a bit unstable.

The latter issue is maybe not so obvious. As a car rolls, the camber and toe

angles will change, and depending on the type of suspension in question

(MacPhearson strut, double wishbone, live axle etc) this will happen in

different magnitudes. MacPhearson struts are particularly susceptible to

this, as they roll they gain positive camber on the outside will in almost

direct proportion to the total roll angle. Obviously keeping roll in check

in this case improves grip considerably as camber angle is pretty critical

to tyre grip.

So what happens when we fit stiffer springs? Stiffening the springs

increases the anti-moment to the roll couple by pushing down harder

on the outside wheel to counteract the outwards roll. We can see

how the stiffness balance between front and rear axles affects 'front

diagonal' and thus oversteer/understeer balance. The stiffer axle pushes down harder

on the outside wheel thus causing a bigger load differential on that

axle and as a result that axle generats less grip than the other, more evenly loaded axle.

So stiffening the springs is great, let's make them rock solid and

the car will handle like a Formula One car, right? Well no, it

doesn't quite work like that, not on the road at least.

Overly stiff springs will transfer all disturbances in the road surface

directly in to the chassis, in doing so this causes excessive load variations

at the contact patches, which will reduce grip over a more consistently loaded

tyre. An oversprung car will also be very quick to respond to driver inputs,

sometimes to the point of being twitchy and difficult to balance on the edge

of grip.

In comparison, a softer spring will allow the wheel to follow

the imperfections in the road surface consistently, and load

up the tyres slower allowing a more progressive feel as the

driver is able to sense the tyres approaching their limits.

Obviously, go too far and we are back at square one with a

sloppy handling but safe car.

So clearly there is a balance to be struck, but how do we know what is ideal?

Introducing the next term in the series, Natural Frequency.

Natural frequency is the relationship between gravity,

a spring and the mass that it supports. Imagine a

mass suspended by a spring. Pull down on that mass

and release it and the mass will oscillate up and

down at a set rate. The rate of this oscillation

is the natural frequency of the system.

It is calculated as such:

$$ F = {1 \over 2 \pi} \cdot \sqrt{\frac{K}{M}} $$

Where:

K = spring rate in (N/m)

M = sprung mass (kg)

Time to bust out the maths again! Argh!

First, let's convert more commonly used units of lb/in and kg/mm into kN/m. We'll use kN/m as the numbers are a bit more manageable.

Math engine has not been started, please change a value to begin...

Next, we need to convert that kN/m spring rate into a wheel rate. Because the springs are mounted inboard

of the wheel, they are subjected to various degrees of leverage depending on the suspension design, which

will work to increase the load on the spring. This has the reverse effect of reducing the spring rate at the wheel

in proportion to the 'motion ratio' of the suspension. The Motion Ratio (MR) is the ratio of wheel displacement to spring

displacement. It's not the easiest thing to measure accurately, so for now we'll make do with some

assumptions. If you car is fitted with MacPherson struts the MR is typically around 0.95, that is

the spring will move .95" for every 1" of wheel movement. For a double wishbone suspension, the damper/spring assembly

is typically mounted further inboard, often mounting to one of the control arms rather than directly to the hub.

Typically the MR on a double wishbone design is closer to 0.7, though it can vary quite a bit. It won't be over

1 unless you've got some sort of weird outboard spring setup.

Actually, MR is sometimes quoted as being more than 1. In this case it is an inverse of the number we are using.

Where we use 0.7, and the wheel rate would be:

$$ \text{Wheel Rate} = \text{Spring Rate} \cdot \text{MR}^2 $$

An MR of 1.43 is actually the inverse, \({1 \over 0.7}\).

The same equation is then simply:

$$ \text{Wheel Rate} = {\text{Spring Rate} \over \text{MR}^2} $$

Both give the same result, just make sure you use them the right way!

So, to calculate wheel rate:

Math engine has not been started, please change a value

Now, let's plug that figure into the ride frequency equation:

Math engine has not been started, please change a value to begin...

This frequency is a standardised value and can be used to directly compare suspension stiffness between completely different

cars, as far apart as an F1 car and a limousine. It simply relates the spring rate to the mass, which dictates the firmness,

think of it like a power to weight ratio for the suspension! Two cars that use completely different spring rates could have

the same comparative stiffness as a result of the weight and motion ratio of the suspension.

So where should we be aiming with this frequency? Generally acceptable standards are as follows:

- Comfortable road car - Up to 1hz

- Sporty road car - 1 to 2 hz

- Occasional track car - 2 to 2.5 hz

- Full track / race car - 2.5 to 3.5hz

- Race car with downforce - Over 4hz

These are ballpark and by no means set in stone, but they are a good guide to go by.

Most performance derivatives of production cars will be in the 1 - 2hz range. For a car

driven regularly on the road, 2.5hz is probably about the maximum you would want to consider, and

even then that might only be truly desirable if you require extra control for weekend track or

autotest events. For a full track car with a decent chassis, frequencies over about 3.5hz do not yield much in

the way of performance increases as the suspension simply becomes stiffer than required. Remember the old

saying: "Any suspension will work, if you don't let it". If you've got good suspension, let it work!

Downforce equipped cars only require such high rates to control downwards body motion and stop the car bottoming out, and

in the case of serious formula series cars, maintain the angle of attack of the wings to a specified operational window.

One thing to bear in mind is that you almost always want to avoid having the rear frequency

the same as the fronts. It's a bit complicated to explain, but basically this can result

in a pitching motion as the front and rear axles move at the same frequency, but out of phase.

This can be an extremely unsettling experience for the driver. General recommended split is about

around 0.2 to 0.3hz for optimum ride comfort, you can then alter this according to the handling balance you want.

So, now we know where abouts we should be aiming, lets have a quick look at what

spring rates we should be considering for the initial setup on our car, based on the weight

weight distribution, motion ratio and design frequency.

The equation is:

$$ \text{Spring Rate} = {M(2\pi \cdot F)^2 \over MR^2} $$

Math engine has not been started, please change a value to begin...

So, now we've got all we need, the mass and distribution, the design frequency and motion ratios. Lets spec the baseline spring arrangement for our car!

Math engine has not been started, please change a value to begin...

So there we have it, we now know how to select an initial spring setup for our car! In the next installment,

we'll take a look at how these spring rates affect the load transfer distribution, investigate revising them to better suit

our handling requirements and introduce anti-roll bars as tuning devices for both the load transfer distribution and the roll angle.

I hope you've enjoyed this article, don't forget to follow Black Art Dynamics on facebook to stay tuned for the next issue if you haven't already!

The Twitter button is inactive at present but I will get that sorted out soon.